CTCG | Our Capabilities

~ Our Equipment, Resources, and Vendors Make Us a Great Choice for Tubing Products

Equipment & Products

CTCG has available for its use a variety of fabrication equipment to facilitate the ease of production of copper tubing products, including heat exchangers and multi purpose tubing coils. In addition to manual tube benders and rotary coiling centers, we employ the use of the following machine tools:

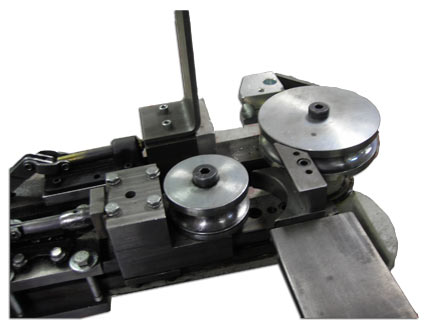

Tube Benders

Both air and hand tube benders are regularly employed for the purpose of manipulating tubing with higher bend resistance, such as in a case with acute bending of tubing with thicker walls.

Mandrels & Turning Centers

We build our coiling mandrels in house and utilize turning centers to coil your products in a state-of-the-art fashion.

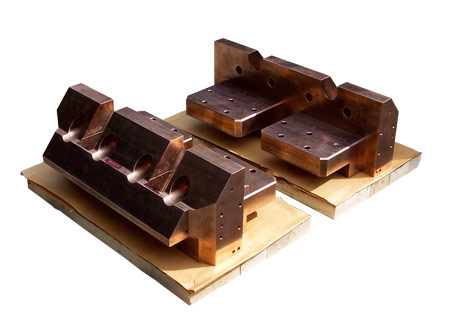

Press Brakes

Where air and hand tube benders fail, press brakes can bend thick copper piping easily and quickly. Our proprietary technology employs the use of in house tooling for the utilization of our 50 and 75 Ton press brakes.

Machining Centers

Where tubing ends, fittings and connectors must begin! For your customized copper tubing fittings and connectors, we have multiple machining centers capable of facilitating low volume ( < 1000pcs) orders.

High Speed Mills

We employ high speed mills to make your tubing fixtures, assemblies, and connectors realistically achievable in the short term.

Vibratory Finishing

For the final look, it's sometimes beneficial to have the best finish. Vibratory Finishing keeps your products smooth and presentable.

Heavy Turning > 17" dia.

Bar Feeding > 3.5" dia.

Does anything you see need improvement? Please email us! improvement@coppertubecoils.com

Other Resources

Our People

Our engineers have been serving the industry for over twenty years and have built Tier 2 or Tier 3 products for companies such as GM.

Our expertise has extended into the fields of plasma research at the University of Notre Dame and continues to be utilized by companies with 21st century technology in the Aerospace industry.

Our Facilities

With a companied square footage of over 55,000 square feet, our facilities are ready to service orders to the hundreds of thousands of parts per month.

Buchanan, MI

Our Vendors

We have been around long enough to know that a company's vendors give it a decisive competitive advantage. Our suppliers are top-notch, world-class, and uniquely suited to keep your price low and your quality high.