Copper Tube Joining, Brazing, Soldering, & End Tube Manipulation Services Provided on a Production Basis to Customer Print

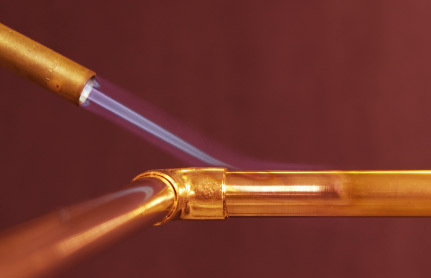

About Tube Joining Using Brazing

Brazing is a method of fabricating copper tubing that renders the connection largely leak-tight. In the process of joining the tube ends, high temperatures cause an "annealing" of the tubing, allowing the localized area to become slightly softer at the site of the braze and tube ends can be fused together. Optimal brazing temperatures range from twelve hundred degrees to fifteen hundred (1,200F - 1,500F). Silver is used for brazing on the cooler end of the spectrum and copper phosphorus is used on the upper end. The "solidus" temperature is where the filler material begins to liquefy. The "liquidous" temperature is when the filler is completely liquid. CTCG employs the use of silver in copper tube brazing.

If substantial "joint strength" is needed, capillary fittings can be used to add more material and consequently reduce weakness in the tube. Brazing is more often than not needed in refrigeration applications.

Pressure-Temperature Ratings of Soldered and Brazed Joints

Joining Material |

Service Temperature (F) |

Fitting Type |

Maximum Working Gage Pressure (PSI), for Standard Water Tube Sizes |

||||

1/8 - 1 |

11/4 - 2 |

21/2 - 4 |

5 - 8 |

10 - 12 |

|||

Ally Sn50 50-50 Tin-Lead Solder |

100 |

Pressure |

200 |

175 |

150 |

135 |

100 |

DWV |

— |

95 |

80 |

70 |

— |

||

150 |

Pressure |

150 |

125 |

100 |

90 |

70 |

|

DWV |

— |

70 |

55 |

45 |

— |

||

200 |

Pressure |

100 |

90 |

75 |

70 |

50 |

|

DWV |

— |

50 |

40 |

35 |

— |

||

250 |

Pressure |

85 |

75 |

50 |

45 |

40 |

|

DWV |

— |

— |

— |

— |

— |

||

Saturated Steam |

Pressure |

15 |

15 |

15 |

15 |

15 |

|

Alloy Sb5 95-5 Tin-Antimony Solder |

100 |

DWV |

1090 |

850 |

705 |

660 |

500 |

Pressure |

— |

390 |

325 |

330 |

— |

||

150 |

DWV |

625 |

485 |

405 |

375 |

285 |

|

Pressure |

— |

225 |

185 |

190 |

— |

||

200 |

DWV |

505 |

395 |

325 |

305 |

230 |

|

Pressure |

— |

180 |

150 |

155 |

— |

||

250 |

DWV |

270 |

210 |

175 |

165 |

125 |

|

Pressure |

— |

95 |

80 |

80 |

— |

||

Saturated Steam |

DWV |

15 |

15 |

15 |

15 |

15 |

|

Alloy E

|

100 |

Pressure |

710 |

555 |

460 |

430 |

325 |

DWV |

— |

255 |

210 |

215 |

— |

||

150 |

Pressure |

475 |

370 |

305 |

285 |

215 |

|

DWV |

— |

170 |

140 |

140 |

— |

||

200 |

Pressure |

375 |

290 |

240 |

225 |

170 |

|

DWV |

— |

135 |

110 |

115 |

— |

||

250 |

Pressure |

320 |

250 |

205 |

195 |

145 |

|

DWV |

— |

115 |

95 |

95 |

— |

||

Saturated Steam |

Pressure |

15 |

15 |

15 |

15 |

15 |

|

Alloy HB |

100 |

DWV |

1035 |

805 |

670 |

625 |

475 |

Pressure |

— |

370 |

310 |

315 |

— |

||

150 |

DWV |

710 |

555 |

460 |

430 |

325 |

|

Pressure |

— |

255 |

210 |

215 |

— |

||

200 |

DWV |

440 |

345 |

285 |

265 |

200 |

|

Pressure |

— |

155 |

130 |

135 |

— |

||

250 |

DWV |

430 |

335 |

275 |

260 |

195 |

|

Pressure |

— |

155 |

125 |

130 |

— |

||

Saturated Steam |

DWV |

15 |

15 |

15 |

15 |

15 |

|

*All tables on this page provided from the copper tube handbook, available from the Copper Development Association.

Does anything you see need improvement? Please email us! improvement@coppertubecoils.com

Get a Quote Today!

Diverse project types accepted. Over twenty years of experience relieving companies like yours of arduous processing. All parts and assemblies built by CTCG are built to customer's exact specifications. Get a quote today for your copper tube heat exchanger design!