Condenser Coils Built to Print

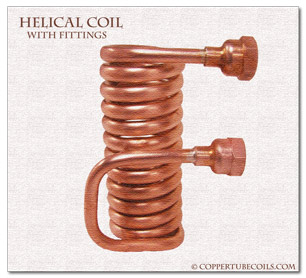

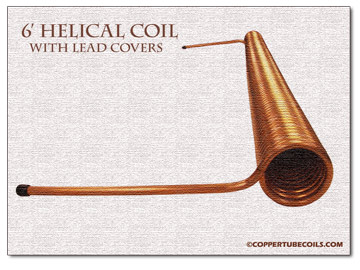

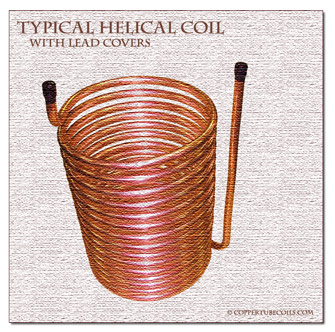

Copper Condenser Coils

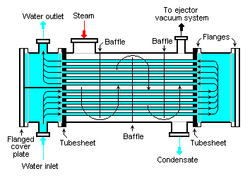

Condensers are one of the prominent uses of copper tubing. Changing gasses into liquids occur at appropriate temperature dew point. Copper's fantastic heat transfer rates are one of the best choices for achieving this goal, exceeding other heat transfer tubing materials (such as aluminum in this case) by nearly 800% while maintaining a strong, lightweight structure. Having a higher heat transfer rate renders less total material necessary for a given space, allowing for more compact, lightweight, and simple condenser applications that minimize back pressure. CTCG builds condensers with copper tubing, aluminum tubing, and stainless steel tubing, to customer prints--but we highly recommend copper tubing for condenser applications.

All Condenser Coil Product Designs Accepted

Whether it be water purification, fluid cooling, chiller applications, air conditioning, steam condensing, steam heaters, steam heated reboilers, or any other heat transfer application, building your products quickly, inexpensively, and in a timely manner is a competitive advantage from which you can profit. Whereas prototypes and production runs of similar products from China can take several months and have spotty quality, questionable material grades, and/or lackluster performance, our Group can deliver prototypes in days and production volume in weeks--depending on the sophistication of your project--with American certified material and repeatable quality.

Whether it be water purification, fluid cooling, chiller applications, air conditioning, steam condensing, steam heaters, steam heated reboilers, or any other heat transfer application, building your products quickly, inexpensively, and in a timely manner is a competitive advantage from which you can profit. Whereas prototypes and production runs of similar products from China can take several months and have spotty quality, questionable material grades, and/or lackluster performance, our Group can deliver prototypes in days and production volume in weeks--depending on the sophistication of your project--with American certified material and repeatable quality.

Does anything you see need improvement? Please email us! improvement@coppertubecoils.com

All Copper Tubing Coil Designs Are Reviewed for Production Runs!

Whether your application is in the Aerospace, ACR, Sprinkler, Heating, or Construction Industries--or any other--CTCG has you covered for copper tube coils. With diverse capabilities and an assortment of options, as well as a broad range of end manipulation and accessories options, CTCG builds copper tube coils to customer print specifications. Get a quote today!

With over twenty years of experience, your project is guaranteed to your exact specifications! Over 97% of our customers return for production runs!