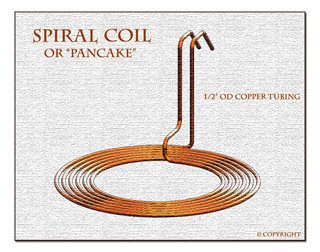

Spiral Coils Built to Print

About the Practicality of Copper Spiral Coils

Spiral coil designs can be an effective use of space in heat tranfer applications. Convection can be improved by switching from an inferior material such as aluminum or stainless steel (though CTCG makes tubing coils out of these materials as well) and adopting a spiral coil design. Finned tubing (though more difficult to manipulate) can add an even further benefit by maximizing the tube's exposure to air and thereby removing more heat. Designers utilizing copper in a spiral design are likely trying to make the best of space though they may not get the best heat transfer rate. Helical coils may experience slightly better performance. Forming spiral coils is yet another specialty of the Copper Tube Coils Group. One positive feature of a spiral coil is that it approaches the maximum space available on a 2D  plane while also allowing some air flow. If your space is limited, a spiral coil may be your best bet. CTCG manufactures spiral coils from customer print designs from copper tubing, aluminum tubing, and stainless steel tubing. The use of copper tubing is highly recommended if heat transfer is to be maximized. Few materials are so well suited to it when it comes to price and effectiveness.

plane while also allowing some air flow. If your space is limited, a spiral coil may be your best bet. CTCG manufactures spiral coils from customer print designs from copper tubing, aluminum tubing, and stainless steel tubing. The use of copper tubing is highly recommended if heat transfer is to be maximized. Few materials are so well suited to it when it comes to price and effectiveness.

Optimizing Your Heat Exchanger Design

When considering your design of a spiral coil, take into account what types of pressure will be exerted on the walls of the tubing and compare with various pressure rating charts for copper. Also consider the material type you intend to use and its heat conductivity. Copper is the standard for its price and effectiveness. While copper is largely benign, does not react strongly with most heat transfer applications, and has a very low risk to use ratio, make sure that the particulates in the tubing do not cause undo damage to the tube over time. Also take into account the maximum amount of pressure rated for the tube so as not to cause erosion corrosion after many years of use. Ensure that your design also has an easy reparability that makes for better replacement of product parts in the future, allowing you to offer competitive warrantees, service & installation charges, and replacement parts.

When considering your design of a spiral coil, take into account what types of pressure will be exerted on the walls of the tubing and compare with various pressure rating charts for copper. Also consider the material type you intend to use and its heat conductivity. Copper is the standard for its price and effectiveness. While copper is largely benign, does not react strongly with most heat transfer applications, and has a very low risk to use ratio, make sure that the particulates in the tubing do not cause undo damage to the tube over time. Also take into account the maximum amount of pressure rated for the tube so as not to cause erosion corrosion after many years of use. Ensure that your design also has an easy reparability that makes for better replacement of product parts in the future, allowing you to offer competitive warrantees, service & installation charges, and replacement parts.

Radiant panel heating is where low temperature hot water circulates through coils or grids of copper tube embedded in the floor or ceiling which allow total use of floor space and eliminate dusty drafts. Because soft Copper Tubing Coils are easy to bend and handle (reducing joints to a minimum), it is often used in curved heating layouts while drawn tube is used for mains and grid heating coils.

The Copper Tube Coils Group Advantage

Whereas prototypes and production runs of similar products from China can take several months and have spotty quality, questionable material grades, and/or lackluster performance, our Group can deliver prototypes in days and production volume in weeks--depending on the sophistication of your project--with American certified material and repeatable quality. Building your products to spec, inexpensively, and in a timely manner is a competitive advantage from which you can profit.

Copper Cooling Coils

Copper cooling coils are used extensively in the ACR industry. Copper is applied a billion times over in air conditioning units and refrigeration because of its fantastic heat transfer properties. While we have had tremendous success with Stainless Steel coils at CTCG in heat transfer applications, Copper is one of the best options available and should not be neglected if quality is a key component in your project!

Air-conditioning and refrigeration systems are the second most common use of copper tube. Usually type L and copper tubes specifically made for the Air Conditioning industry (ACR Copper Tubing) are used for these applications.

CTCG builds cooling coils for customers with designs they wish to implement. Among the applications are simple air conditioning condenser coils.

Does anything you see need improvement? Please email us! improvement@coppertubecoils.com

All Copper Tubing Coil Designs Are Reviewed for Production Runs!

Whether your application is in the Aerospace, ACR, Sprinkler, Heating, or Construction Industries--or any other--CTCG has you covered for copper tube coils. With diverse capabilities and an assortment of options, as well as a broad range of end manipulation and accessories options, CTCG builds copper tube coils to customer print specifications. Get a quote today!

With over twenty years of experience, your project is guaranteed to your exact specifications! Over 97% of our customers return for production runs!